-

More than 20 years Experience,Orbit Intelligent Engineering

-

“Orbit Intelligent Engineering” is a well-known manufacturer, exporter of almost qualitative assortment automatic fly ash brick plants, automatic ash brick plant. Integrated in the year 2004, at Mehsana (Gujarat, India), a completely new sanitary ware project with casting area was awarded, so create a healthy working environment for the employees so that automatic fly ash brick plant.

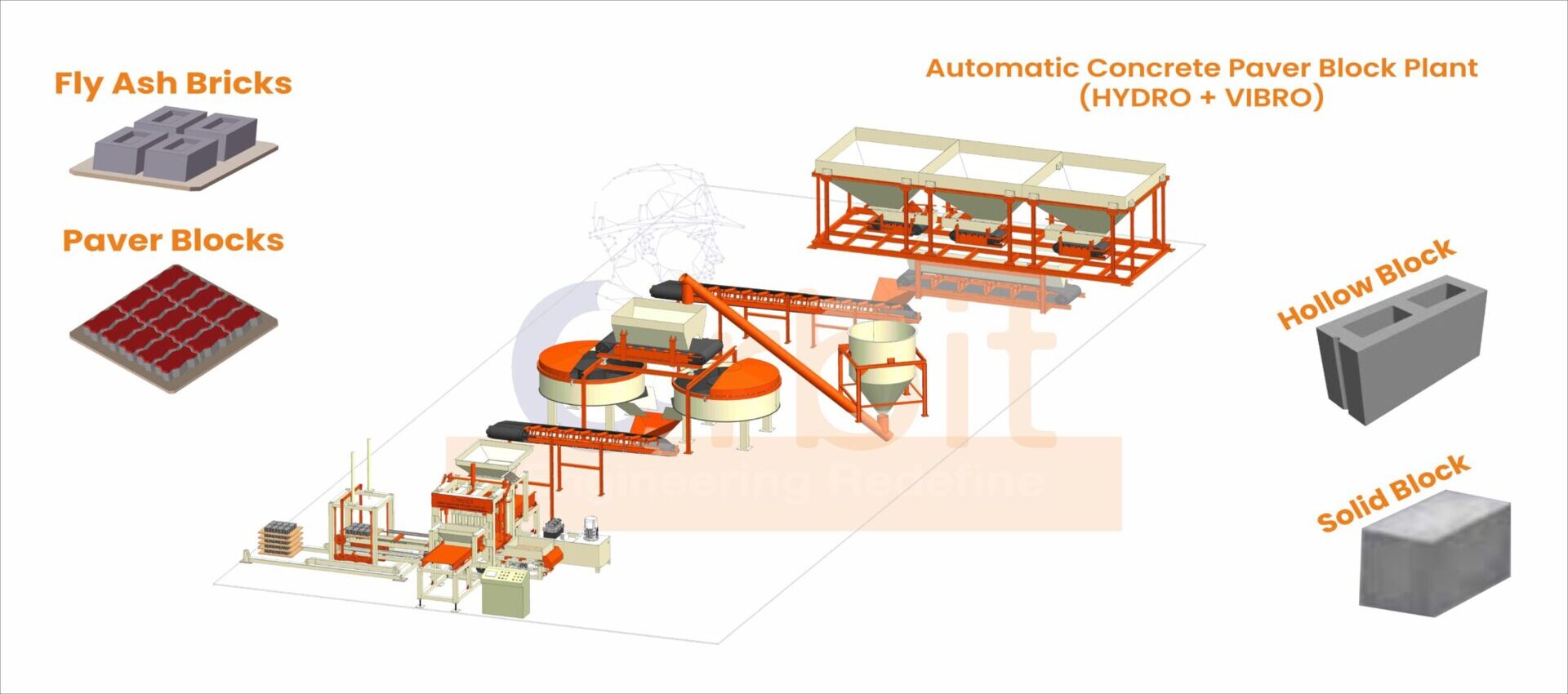

Automatic fly ash brick Plant

We are providing complete turnkey projects for fly ash bricks, concrete blocks (hollow/solid), interlocking concrete/paving blocks, curbs, etc., with a limit of 10,000 to 1,20,000 pcs / day with plants Auto Batching and Auto Clave. Our flying debris block-making machine can produce blocks of any shape and size.

Read More

Automatic Paver Block Plant

We are a producer, supplier of garbage landslide machines (FAM-720). This machine has a throughput of 8 blocks in one go. Planned Water Jet & Floating Debris Slip Production Machine (FAM-720). incorporates solid vibrators, conveyors, container mixers, etc.

Read More

DEPENDABILITY

Orbit Intelligent is the pioneer in Fly Ash Brick Plant Manufacturing, Commitment is the backbone of our company

Modern Technology

For an outstanding product quality. Error free operations & product development facility to deliver the best solution and products.

Professional Team

We have highly trained team of Engineers & Expert who make sure that the clients gets the best of products.

ANNUAL MAINTENANCE

Annual Maintenance Contract ( Comprehensive and Non-comprehensive)